OFFSHORE ENERGY

Oil & Gas

More than 25 years of engineering experience covering the full range of offshore activities from pre-feasibility through pre-FEED, FEED, detailed design, and installation management.

Feed & Design

From field prospect and economic evaluation to the design and analysis of fixed and floating production systems, subsea architecture, and rope technology.

Operational Efficiency

Using advanced analysis techniques, AMOG can help you operate more efficiently and maximise uptime.

Life Extension

Asset-based management strategies, Anomaly Assessments, and Risk Based Inspection (RBI) techniques can help extend the life of aging assets.

Decomissioning

Abandonment studies and validation of Safety Plans

AMOG Consulting has a proven track record in the provision of leading engineering solutions to the offshore energy industry. AMOG’s experience covers the full range of offshore activities from pre-feasibility through Pre-FEED, FEED, detailed design and installation management.

In order to ensure that our knowledge base remains at the leading edge of practice, AMOG maintains a close affiliation with the world’s leading universities and is actively involved in the conduct of in house and funded research projects, as well as the state of the art projects we are involved in performing for major international exploration and production companies. Where the use of such leading edge solutions/technologies is necessary to meet the requirements of challenging fields, AMOG maintains a focus on the practical realities of offshore operations by ensuring that safety, technical and project risk are kept to a minimum, thus keeping costs down.

AMOG is able to support clients by offering the following offshore oil and gas services

- Specialist Engineering Design & Analysis

- Risk Assessment & Safety Engineering

- Infrastructure Support and upgrade

- Legal and Expert Witness

- Software

- Training

AMOG is able to perform design analyses using advanced numerical techniques and state of the art software, covering a broad range of issues pertinent to the design and installation of mooring and riser systems. Our expertise and experience in VIV analysis extends to our key role in the development and maintenance of SHEAR7, the industry leading tool for the prediction of VIV effects.

AMOG have a number of qualified staff who have completed Basic Offshore Safety Induction and Emergency Training (BOSIET) through an accredited agency. We therefore have the ability to deploy qualified senior members of staff at short notice, should you require AMOG’s structural, naval architecture, risk and safety, or installation services on offshore sites including FPSOs.

AMOG is able to undertake field prospect and economic evaluation using in-house databases and facility sizing tools along with the industry leading cost estimation packages.

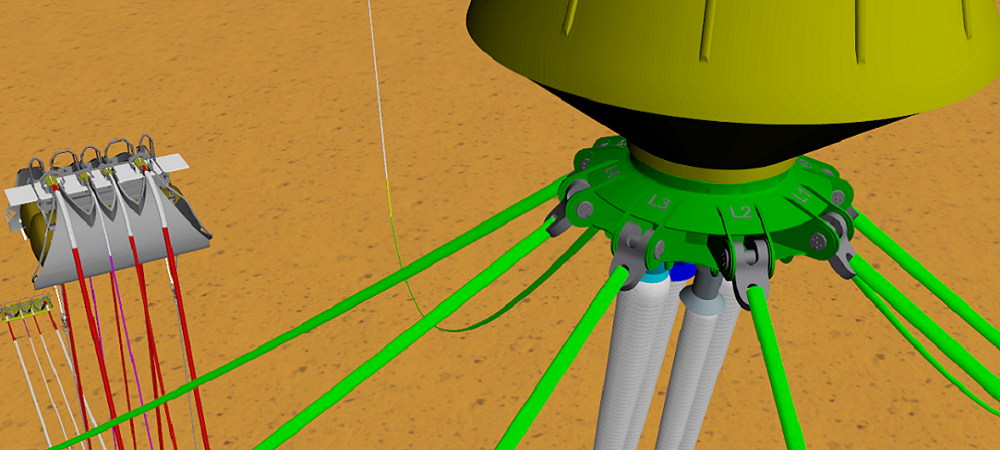

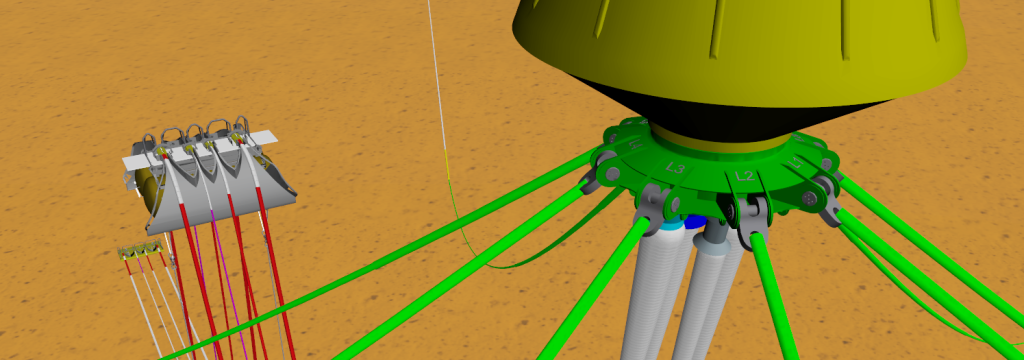

We can provide a wide range of services in relation to field architecture and sub-sea engineering; from high-level layouts to account for work-over activities and dropped objects, to detailed analysis of sub-sea flow line installations, to well-heads. AMOG is also able to conduct tie-in studies in which high level piping, flow-line and control systems are developed. We offer studies and reports on:

- Field layout design and drawings

- Preferred field architecture based on risk drivers

- Key risk drivers affecting field layout

- Risk deduction mitigation methods

- Stabilisation requirements of sub-sea equipment

- Control pod and umbilical requirements

- Foundation and Skit requirements for sub-sea equipment

- Model testing of dropped and dragged objects

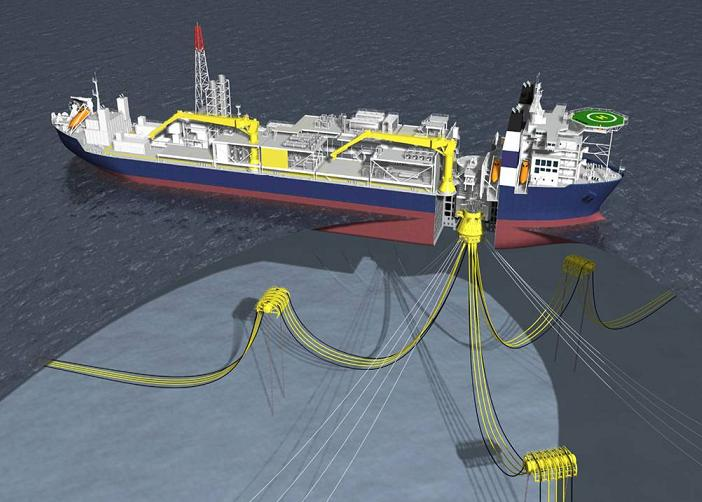

When it comes to the design and analysis required for FEED studies, AMOG has extensive experience and can draw on a large in-house library of floaters, turrets, mooring systems, riser configurations, and metocean data to help select, benchmark and define concepts. Our specialist areas of expertise include floating production systems as well as subsea pipelines/sub-marine cables, rope technology, and;

Hull Forms

- Tanker based FSO/FPSO

- Spar

- Semi-Submersible

- TLP

- Barges

- CALM

Riser systems

- Flexible riser systems

- Top-tensioned

- Steel catenary

- Hybrid

- Single leg offset

Mooring systems (incl disconnectable)

- Chain

- Wire rope

- Synthetic rope

- Infield and cyclone moorings

AMOG is also able to provide technical reviews of tenders for mooring equipment, riser and umbilical systems, turret arrangements, and fluid transfer systems. Our services the technical and commercial mattes pertaining to tenders, preferred suppliers based on a transparent and independent technical evaluation of supply documentation, non-compliance to tenders, and key areas of technical, commercial, schedule and contractual risk within tenders.

Our carefully designed and managed Inspection and Maintenance routines are essential to the longevity of any marine infrastructure. AMOG’s design team can optimise your solutions to meet cost, fatigue, operational, and environmental constraints.

There will always be a requirement – whether imposed by regulators or as part of best practice infrastructure management – to conduct inspections on key structural and safety elements, and to perform the appropriate preventative and corrective maintenance when necessary.

Using advanced analysis techniques and state-of-the-art software, AMOG has extensive experience in the analysis of the dynamics of a wide range of:

Hull Forms

- Tanker based FSO/FPSO

- Spar

- Semi-Submersible

- TLP

- Barges

- CALM

Riser systems

- Flexible riser systems

- Top-tensioned

- Steel catenary

- Hybrid

- Single leg offset

Mooring systems (incl disconnectable)

- Chain

- Wire rope

- Synthetic rope

- Infield and cyclone moorings

AMOG is also able to provide technical reviews of tenders for mooring equipment, riser and umbilical systems, turret arrangements, and fluid transfer systems. Our services the technical and commercial mattes pertaining to tenders, preferred suppliers based on a transparent and independent technical evaluation of supply documentation, non-compliance to tenders, and key areas of technical, commercial, schedule and contractual risk within tenders.

We are also able to develop complete documentation packages including operation and maintenance manuals. commercial mattes pertaining to tenders, preferred suppliers based on a transparent and independent technical evaluation of supply documentation, non-compliance to tenders, and key areas of technical, commercial, schedule and contractual risk within tenders.

As a more cost-effective solution, the offshore oil and gas industry is increasingly looking to extend the life of ageing production assets past the original design intent.

The challenges to increased life include; ensuring integrity given potential modifications to the floating or fixed asset, modifications to the loading design conditions over their service life, as well as the accumulative effect of fatigue loading on key structural components.

AMOG has looked at the adoption of reliability methods for re-certification and life extension, particularly when dealing with less tangible residual life criteria.

Now, advances in condition monitoring for moored FPSOs and fixed offshore platforms, combined with risk-based inspection criteria are assisting in extending the operation of productive assets beyond their original design life, whilst minimizing ongoing costs.

In particular, AMOG’s work in the area of Mooring Integrity Management (MIM) is now being developed for Model Guidelines for MIM.

When is comes to the decommissioning and abandonment of offshore assets, AMOG can assist with specialist abandonment studies and the validation of Safety Plans.